Top 5 Major Causes of PCB Failure

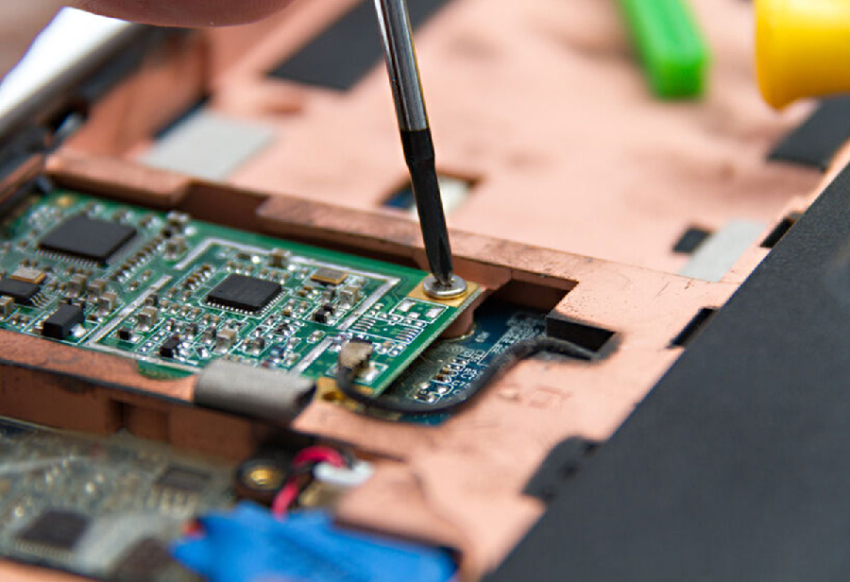

Printed circuit boards are used in almost all electronic devices used in many industries. These boards can be found in smartphones, cars, computers, street lights, display screens, microwaves, imaging machines, and many more. When printed circuit boards malfunction, they can impact our personal and even business lives. PCBs can fail for a variety of reasons and you need to understand the causes of these failures to prevent them in the future and be more productive during the testing process. PCBs can fail because of the following reasons.

Defects

This is one of the most common causes of PCB failure. In most cases, defects may occur during the PCB manufacturing process. Printed circuit boards tend to be sensitive to electrostatic charge or ESD and even the smallest discharge of ESD may cause component defects. The defects may be latent where your PCBs remain functional but have downgraded reliability. \they can also be catastrophic in that permanent damage occurs. Reliable manufacturers will take all precautions to eliminate potential electrostatic discharge including shoe grounders, dissipative floor or work surfaces, and ESD-safe smocks from the production floor.

Environmental Factors

Circuit boards tend to be quite sensitive to environmental factors too. Humidity and heat may cause expansion of PCBs causing warping and damaging soldered joints. This is why PCB assembly is usually done in climate-controlled environments to keep humidity at a safe level. Foreign debris that gets to your board can also affect the boards causing overheating, for example, hair, dust, liquid, and even fibers.

Age

Printed circuit boards tend to break down as they get older. When components reach their expected life cycle, they will start to fail. Therefore, the PCB needs to be replaced or fixed with a new one. In most cases, PCBs can be fixed for just a small percentage of the cost of getting a new PCBs. This means that businesses should have contacts with PCB manufacturing companies that provide aftermarket services.

Burnt Components

Burning of PCB components is a major cause of failure and can result in not just a part replacement but a rework of the entire board. Burnt components can be caused by extreme heat especially when machines overheat or the board is exposed to open fire. In addition, improper spacing of components can cause them to heat up affecting the performance of nearby parts. This problem can be eliminated by ensuring optimum amount of space between different components.

PCBs are also at risk of burning out if the board is not correctly hooked up or voltage protections are not to standard. A detailed hook up instruction manual can help to eliminate technician error or component failure.

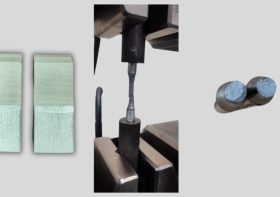

Soldering Problems

In the PCB assembly process, soldering is an essential ingredient. Solder is what helps to maintain contact between components and the circuit. However, if the solder is contaminated, it cause failure of the board. Excess moisture in the solder will become conductive resulting in short circuiting. Solder installation errors can also cause failure of PCBs, for instance, defects like excessive solder, opens, components shifting, lifted pads, solder bridges, cold joints, and webbing and splashes. Proper training and extensive practice for assemblyexperts can help in eliminating soldering defects.

Most of these printed circuit board failures can be addressed by reworking on them after extensive inspection and analysis. However, it is always best to avoid or lower the risks of failure by working with a seasoned and reliable PCB manufacturing company. This will not only save you time and money, but will guarantee the reliability of your electronic devices.