Importance of Using the Micro Channel Exchanger

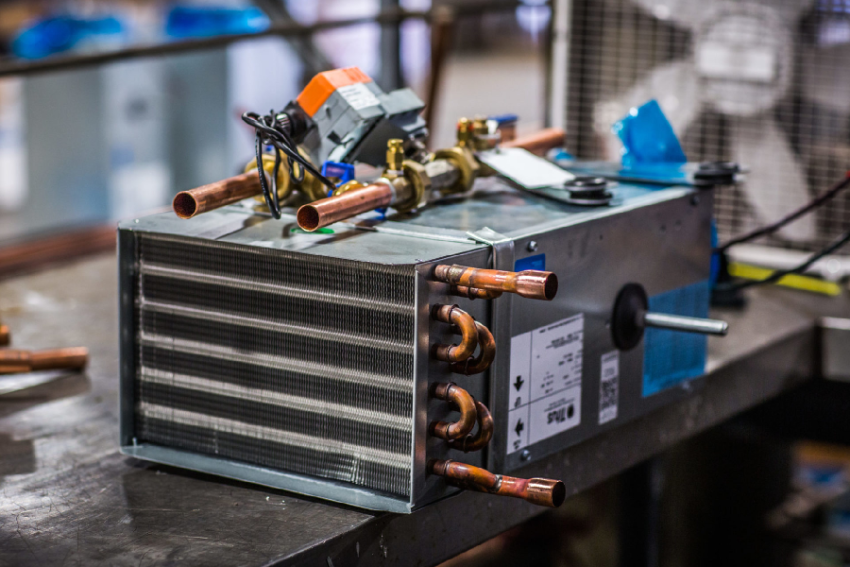

As per the environmental legislation, it affects the major product recycling potential and refrigerants and another microchannel heat exchanger . The top leading company manufacturer is here to optimize the products to control the overall heat. Obsessively the Aluminium product solves such issues due to the physical properties, and it can be extruded to extremely tight tolerances, and steel copper cannot. Therefore most companies manufacture Microchannel tubes to reduce the overall heat energy from the cooling system. The microchannel heat exchanger is made with aluminum, which is lighter, and the cost is less expensive compared to the other copper material. It shows that three-meter of the aluminum tube for the price of one meter of copper material.

Microtechnology:

With the help of the microchannel technology, it has a combined tube with others slotted to the welded aluminum manifold. It allows exploiting the potential when comparing all-aluminum solutions offered. This new technology lets the company minimize the overall system refrigerant charge by up to 40%, and it develops the overall energy of performance by up to 10%. Then reduce the overall Rae material, which needs more than 50 %. It minimizes the cost of using the aluminum and is simple to recycle the all-aluminum system satisfactorily.

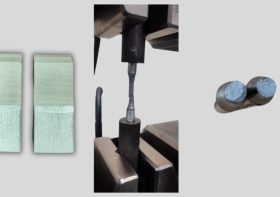

Design:

With a cool design, it has a flat, microchannels tube and strip, and as a result, it performs better in high heat. Based on the application, it is oriented in the form o horizontally. It ensures the predictable heat exchanger performance and state-of-the-art finish design, which Lowe airside the overall pressure drop and high heat transfer.

It has a different type of connection along with the custom orientation. It has a rubber insert to prevent the contact of aluminum and other metal from cutting down the corrosion. With the help of the coil itself, it has a robust frame that offers airtight flush mounting and reduces the unwanted framing component when the air gets bypassed. Therefore, you must go with the right company to buy such an exchanger to reduce the overall heat in the various HAVC device. Before going to inverse money on such a device, you need to ensure the company and its product so that it committed to offering the full range of devices with special features and support at all times.

Features and advanatage:

Using 20% to 40% of the heat transfer always performs better, and it ensures to lower airside the pressure drop in a winning way. On the other hand, it reduces the 10% top 30% of the least coil will face according to the design condition, and the overall weight is to low up to 60%. It is manufactured with higher corrosion resistance and built with robust construction support, which reduces the overall heat produced by the different machines. It has a low refrigerant charge of up to 60% and a well-optimized raw material cost, so it becomes more comfortable to use such a microchannel heat exchanger to reduce the overall heat. Hope it gives more comfortable to use and reduces the overall heat.